Spray Painting

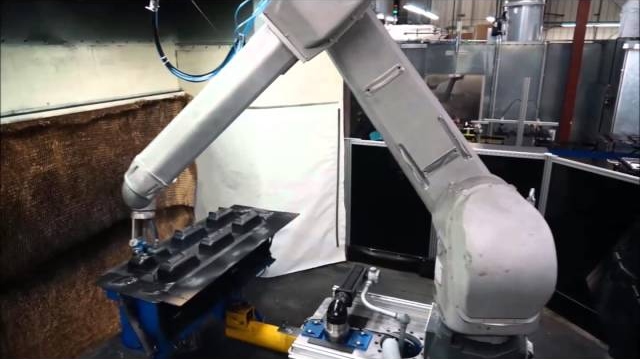

Utilizing the latest technology in industrial spray painting for a variety of plastic surfaces, Apex Plastic Finishing Company combines manual craftsmanship with robotic technology. Our 4 industrial robotic paint lines feature computerized fluid control and monitoring, allowing for computer controlled arms to maximize paint speed, accuracy, and consistency. Our seasoned staff also provides manual painting services, delivering the best reputation in the industry for plastic spray painting. All our paint lines are equipped with automated drying tunnels. Apex is experienced and capable of helping our customers minimize cost and increase production efficiency for high volume jobs.

We offer an array of paint and texture capabilities, including decorative finishes, RFI shielding, structural foam surfacing, and custom masking using materials such as lacquer, waterborne, high solids, and two component paint systems. We always achieve repeated accuracy and tight tolerances for any paint project, including the automotive industry. Our team has worked with epoxies, urethanes, water/solvent based, polyurethane, and acrylic lacquer paints on various plastic surfaces. For specialized coating needs, we offer a number of characteristics for any application. Utilizing state-of-the-art spray painting technology in our 25,000 sq. ft. facility, we offer specialty production, prototyping, low or high volume, and small or large scale production volume runs. We also work with our partners on consulting, development, engineering, and complete inspection services for any simple or complex project.

As an ISO 9001:2015 company, we strive to surpass industry standards through the use of innovative and computer controlled systems for project versatility and on-time delivery. We’ve delivered painted plastic surfaces for numerous companies in the automotive, aerospace, architecture, consumer electronics, medical, and military industries. With flexibility and reliability, we can provide emergency services or rush orders when possible. To learn more about our spray painting capabilities, please contact us for more information or refer to the table below.

Spray Painting Highlights

- Capabilities

-

- Decorative Finishes

- RFI Shielding Applications

- Computerized Fluid Control & Monitoring

- Custom Masking Available

- Consistent Quality

- Paint & Texture Capabilities

- Repeated Accuracy & Tight Tolerances for today’s automotive industry

- Capable of applying a variety of materials:

-

Lacquer

Waterborne

High Solids

Two-Component Systems

- Coating

-

Epoxy

Urethane

Water/ Solvent Based

Polyurethane

Acrylic Lacquer

- Substrate

-

Plastic

- Coating Characteristics

-

Abrasion Resistant

Chemical Resistant

Shielding Capabilities

Color Addition

- Additional Services

-

Consulting

Development

Engineering

Inspection

- Production Volume

-

Specialty Production Shop

Prototype

Low Volume

High Volume

Large Scale Production Volume Run

- Lead Times Available

-

Quoted on job by job basis

Emergency services available when possible

Rush Services Available when possible

Additional Information

- Industry Focus

-

Aerospace

Agricultural

Architectural

Automotive/ Car/ Truck/ Trailer

Consumer Electronic

Machine Tool

Medical

Military

POP Industry

Pharmaceutical

- Industry Standards

-

ISO 9001:2015

Subscribe to Our E-Newsletter

Enter your email below and you will be the first to know about:

Special Promotions, and Upcoming Events!