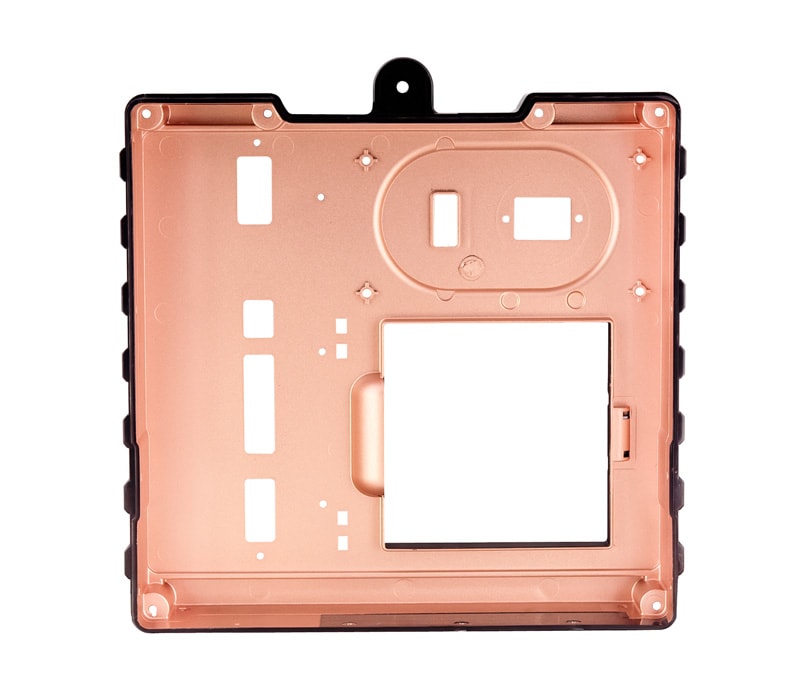

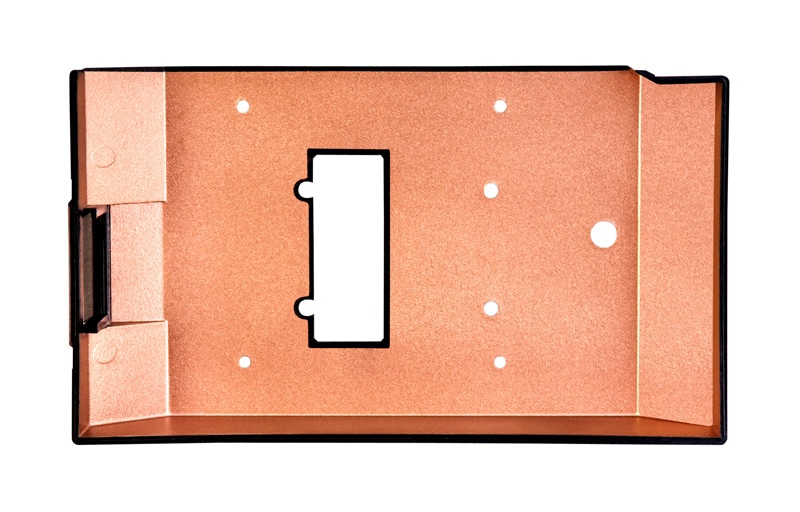

EMI/RFI Shielding

We’re one of the nation’s leading service providers for EMI and RFI shielding of plastic parts using copper and nickel coatings. We’re experienced in helping customers develop various production methods for shielding simple or complex products. With over 45 years of work in EMI and RFI shielding, we can provide automatic or hand masking techniques for high or low volume jobs.

We are always seeking to innovate our technology, allowing us to increase our production speed, versatility, and efficiency for EMI and RFI shielding projects. Our goal is to reduce overall costs for our customers using the latest equipment available in the industry. We are a customer-centric company, providing turnkey consulting, development, engineering, and inspection services on every project. Our 25,000 sq. ft. facility will accommodate shielding paint services for low or high volume, large scale, prototyping, and specialty production runs.

Focused on quality control, we’re an ISO 9001:2015 certified company that specializes in quick turnaround times and precision results. Our workmanship is widely utilized by companies in the aerospace, automotive, medical, military, and architectural industries. To learn more about our EMI and RFI coating processes, please contact us for more information or refer to the table below.

EMI / RFI Shielding Highlights

- Capabilities

-

Automatic Masking for High Volume Jobs

Hand Masking for Low Volume Jobs

Experienced in helping customers develop methods to shield products

- Coating

-

Copper

Nickel

- Substrate

-

Plastic

- Pre-coating Preparation

-

Adhesion Promoter

Hand Masking

Priming

- Additional Services

-

Consulting

Development

Engineering

Inspection

- Production Volume

-

High Volume

Large Scale Production Volume Run

Low Volume

Prototype

Specialty Production Shop

- Lead Times Available

-

Quoted on job by job basis

Subscribe to Our E-Newsletter

Enter your email below and you will be the first to know about:

Special Promotions, and Upcoming Events!